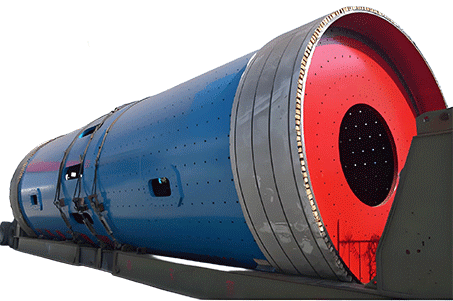

Grinding Ball Mill For Sale

For businesses in mining, construction materials, and chemical processing, the grinding ball mill remains a cornerstone of production. Our grinding ball mill combines robustness, high capacity, operational flexibility, and proven technology, making it a reliable and often optimal choice for achieving efficient and controlled size reduction.

Primary Industrial Applications:

Mining & Mineral Processing: Grinding ore (copper, gold, iron, lead-zinc) to liberate minerals for separation (flotation, leaching).

Cement Production: Grinding clinker and gypsum to produce the final cement product.

Chemicals & Paints: Manufacturing fine pigments and chemical powders.

Power Generation: Pulverizing coal for combustion in thermal power plants.

Ceramics & Advanced Materials: Preparing raw materials and glazes.

Grinding Ball Mill Advantages

Wide Adaptability

Capable of grinding a vast spectrum of materials, from extremely hard and abrasive ores to softer minerals and chemicals.

Process Flexibility

Can be configured for both wet and dry grinding processes, allowing you to choose the method that best suits your product specifications and downstream processing needs.

Precise Control

Adjustable grinding media, mill speed, and feed rate to precisely control particle size for a consistent, high-quality product that meets strict specifications.

High Capacity

Engineered for continuous, 24/7 operation, delivering consistent, high-volume output. They are the standard for high-tonnage industries like mining and cement, with models available to scale from pilot projects to full-scale production lines.

Provide Full Range of Mining Grind Solutions

Global Manufacturing Excellence

Boasting a global clientele of 80,000+, our operations are powered by 100+ front-line staff, 30+ engineering technicians, and 100+ units of large/medium machining, welding, and assembly equipment, with full support for custom specifications.

Proven Reliability and Simple Operation

Our technology is mature and mechanically straightforward, leading to high operational availability (uptime) and predictable performance. With fewer complex components than some alternative grinders, they are robust and built to last for decades with proper maintenance.

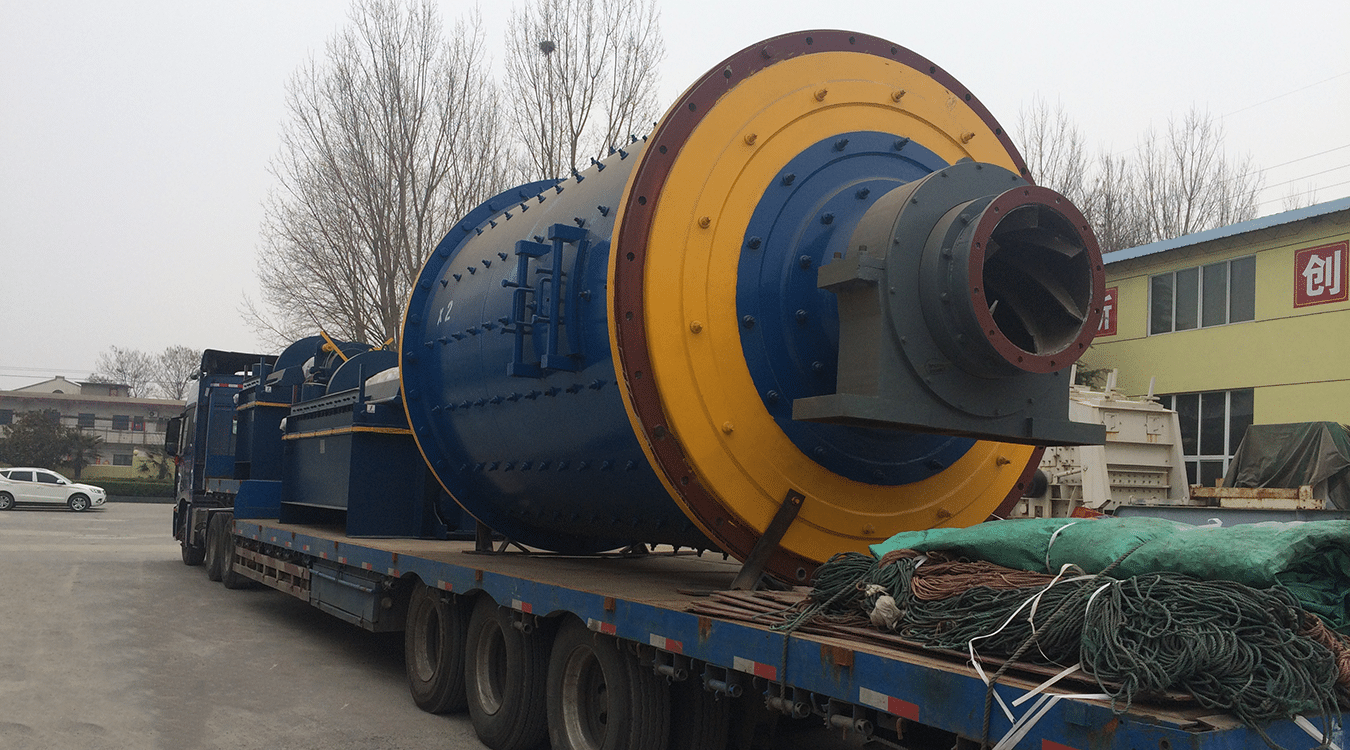

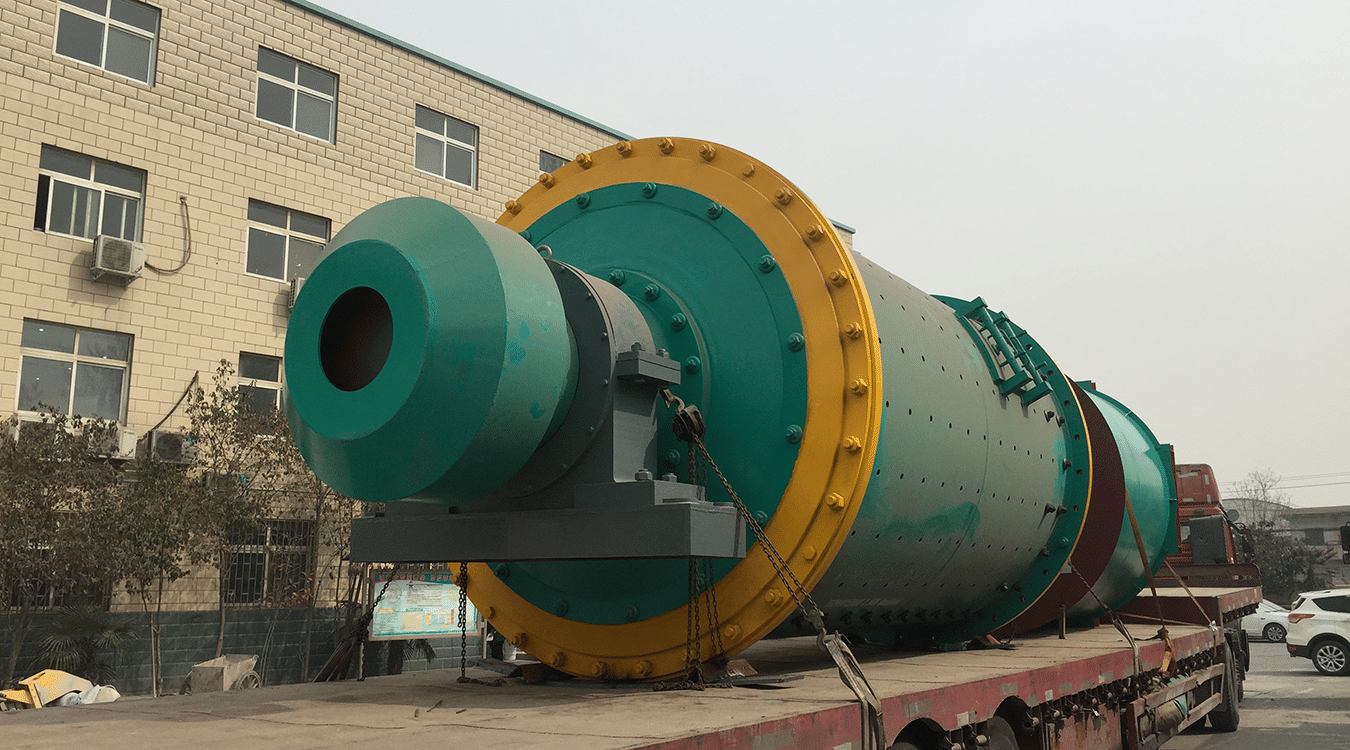

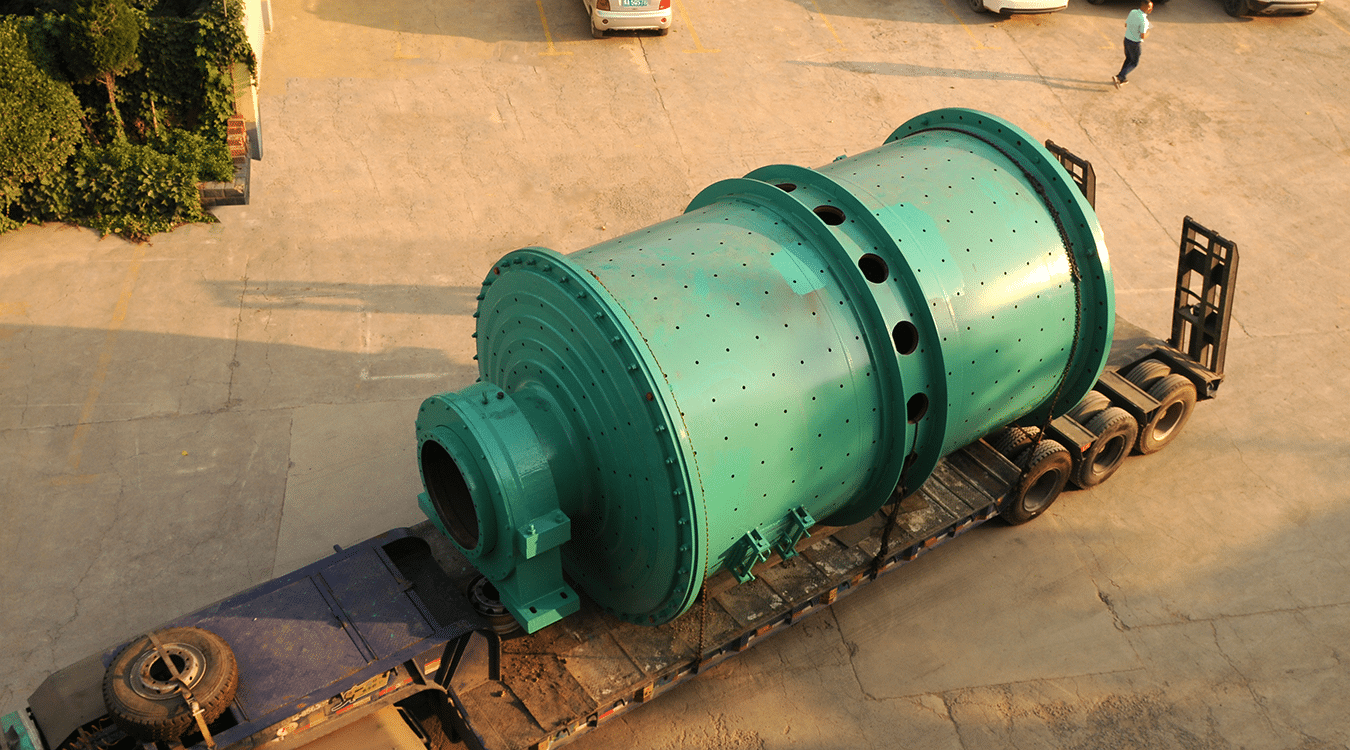

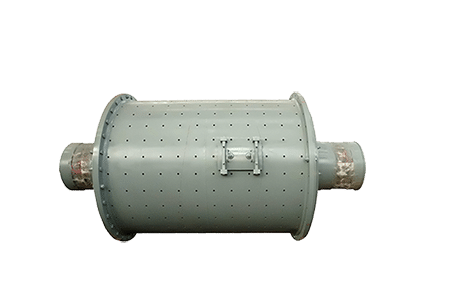

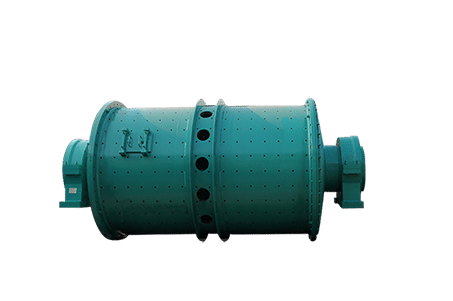

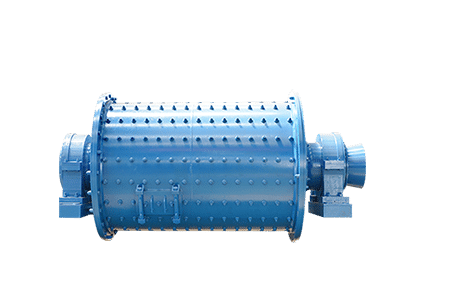

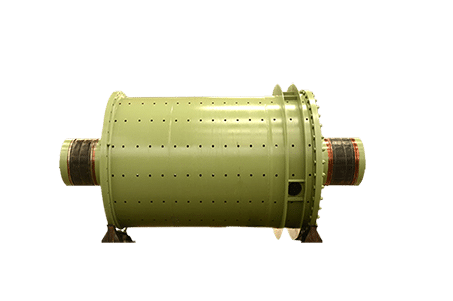

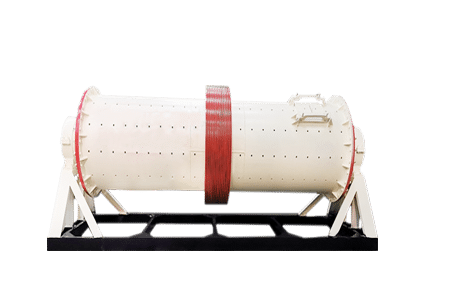

Our Ball Mill Line Solutions

Our ball mills are designed for the large-scale reduction of material particle size through impact and abrasion. It is the workhorse of many processing industries, engineered for continuous, high-tonnage operation in demanding environments. Here are some of our recent solutions:

Granite Sand Production

Copper Ore Flotation

Gravel Sand Production

River Pebble Sand Making

Happy With Customers & Clients

With a proven global footprint, we are proud to serve over 80,000 clients across more than 120 markets worldwide. This extensive reach reflects our commitment to quality, reliability, and customer-centric solutions, enabling us to meet diverse industrial needs and deliver exceptional value on an international scale.

The fineness and quality of our cement have significantly improved. Your mill provides exceptional particle size control, resulting in a more consistent and higher-quality product that has strengthened our brand in the market.

Bruno william

– Brazil

Ball Mill Manufacturer Business Strength

We are a global leader in the design, engineering, and manufacture of high-performance grinding equipment, specializing in robust and efficient ball mills. Our dedicated research and development team continuously innovates, integrating advanced materials science and grinding dynamics to enhance mill efficiency, reduce energy consumption, and extend component life.

80000+㎡

Plant Construction

100+

Production Machinery

120+

Marketing Countries

We Promise High Quality & Best Price